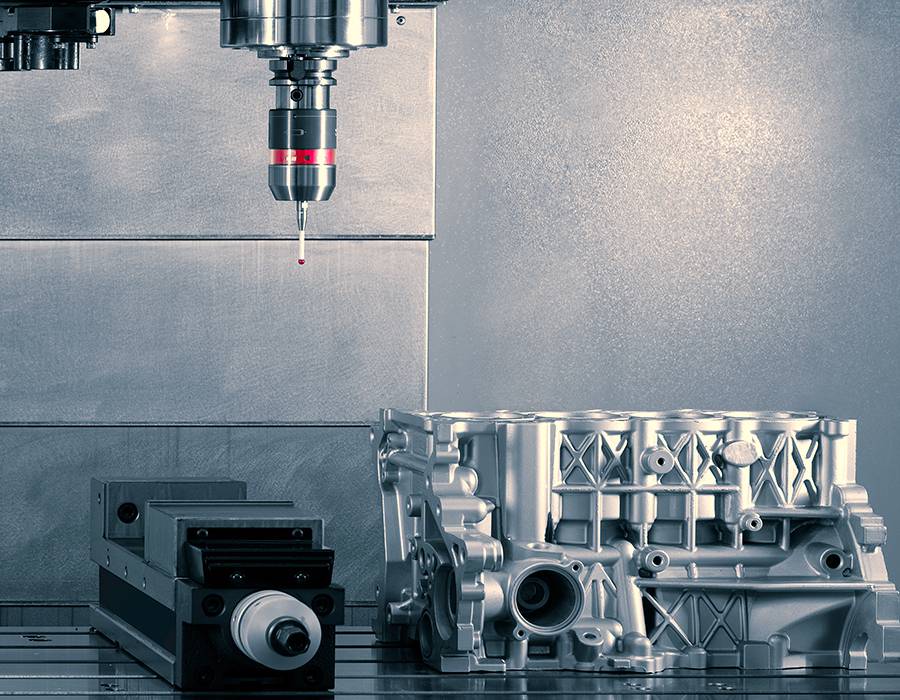

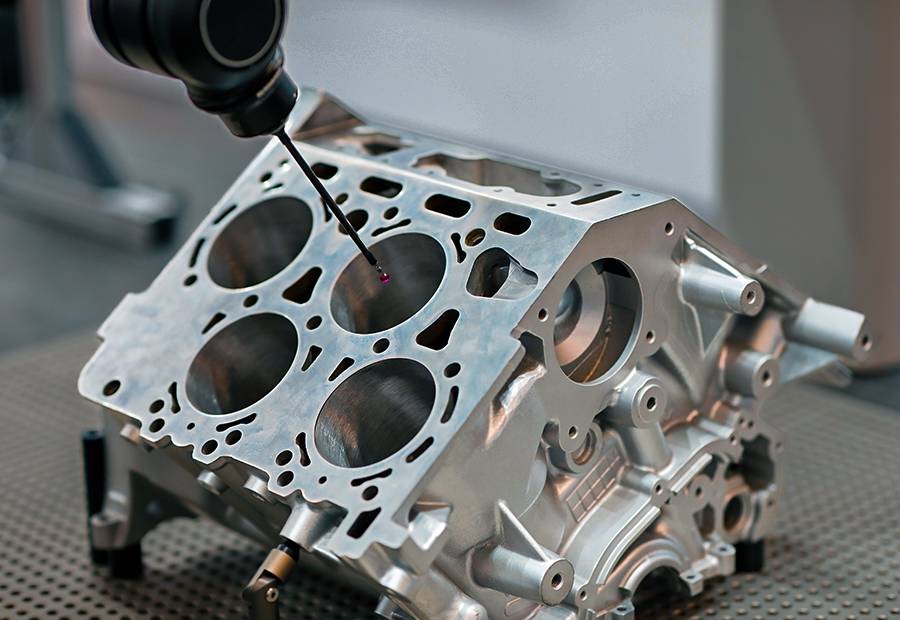

CNC Custom Inspection Capabilities

RAM Tool, Inc. is a leading provider of CNC contract milling services. Our team of experienced machinists uses state-of-the-art CNC milling to deliver precision and accuracy in every project. We work with a variety of materials and we serve several industries. Our commitment to quality and customer satisfaction has made us a trusted choice for businesses in need of reliable CNC contract milling and precision machining capabilities.

Get

Get