CNC Machining Process

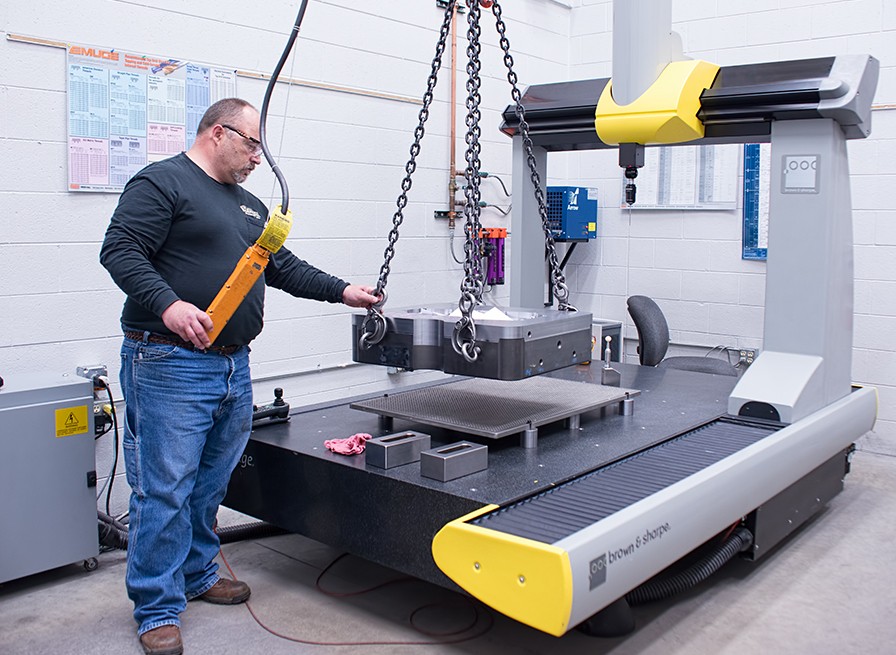

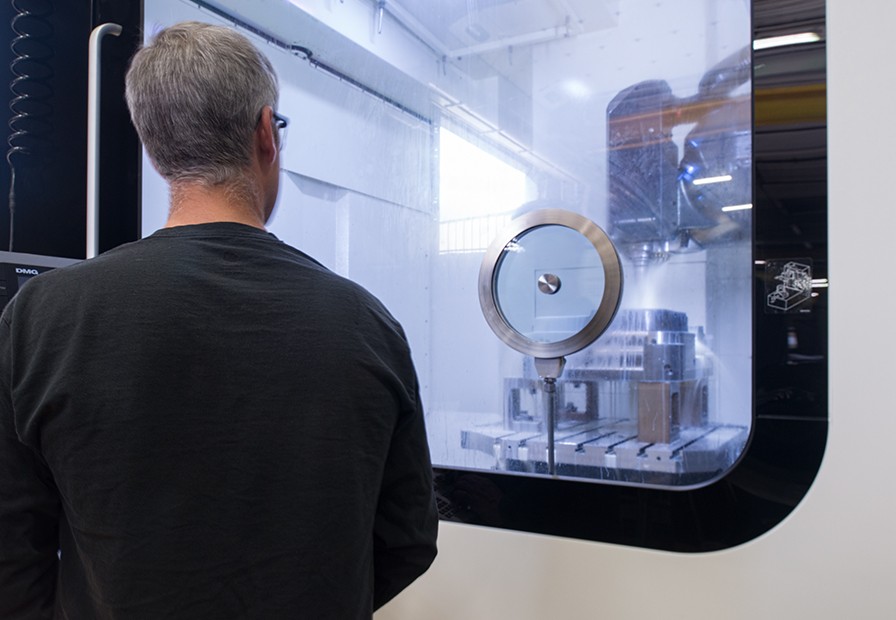

RAM Tool’s Precision CNC Machining Process from Start to Finish

RAM Tool follows a proven CNC machining process built on precision, efficiency and strict quality control throughout over four decades of experience. Each project moves through a structured workflow supported by advanced CNC consulting, material management and production expertise at our state-of-the-art facility.

Our engineers guide every step so parts move from concept to production with predictable performance and repeatable accuracy. Contact us today to request a quote.

Get

Get