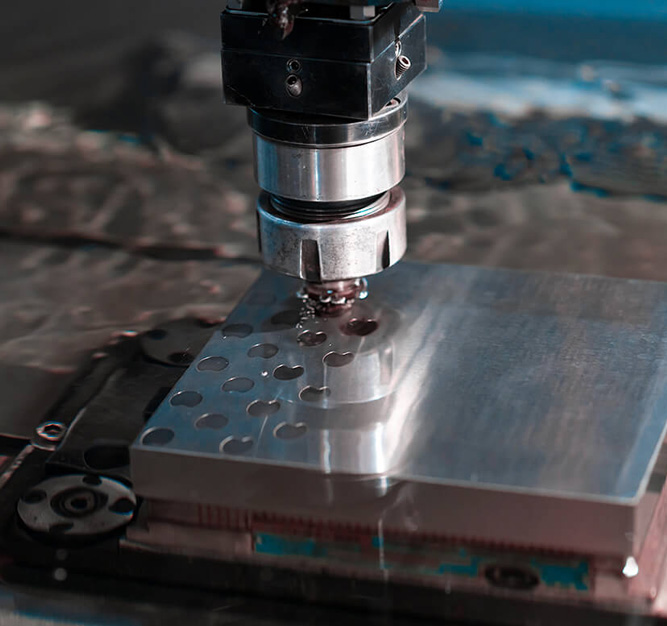

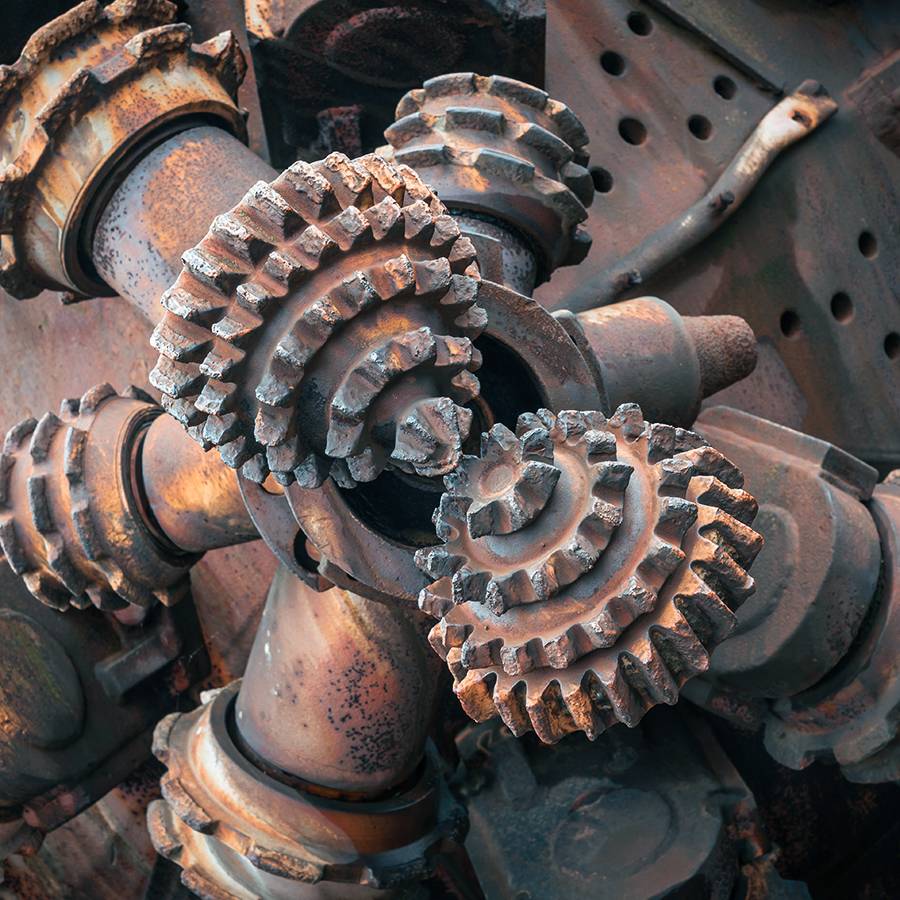

CNC Machining for Mining Equipment

RAM Tool delivers precision CNC machining for the mining industry, manufacturing parts designed to perform under extreme stress and environmental conditions. Our components support heavy machinery, drilling systems and processing equipment across mining operations worldwide. With advanced technology and dependable turnaround, RAM Tool helps mining companies maintain productivity, reduce downtime and extend equipment life.

Contact RAM Tool today to discuss CNC machining for the mining industry.

Get

Get

The CNC Advantage

The CNC Advantage