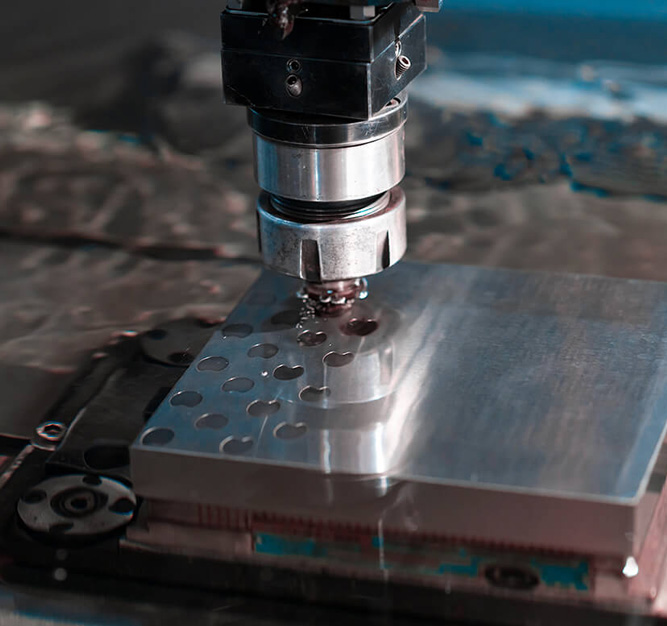

CNC Machining for Powersports

RAM Tool delivers precision CNC machining for powersports, producing high-performance parts for motorcycles, ATVs, snowmobiles, UTVs and marine vehicles. Our advanced machining processes support OEM production and aftermarket performance components, providing tight-tolerance accuracy to enhance safety, efficiency and durability. From engines to suspension systems, we supply the precision parts powersports manufacturers depend on.

Contact RAM Tool today to discuss CNC machining for your powersports project.

Get

Get

The CNC Advantage

The CNC Advantage