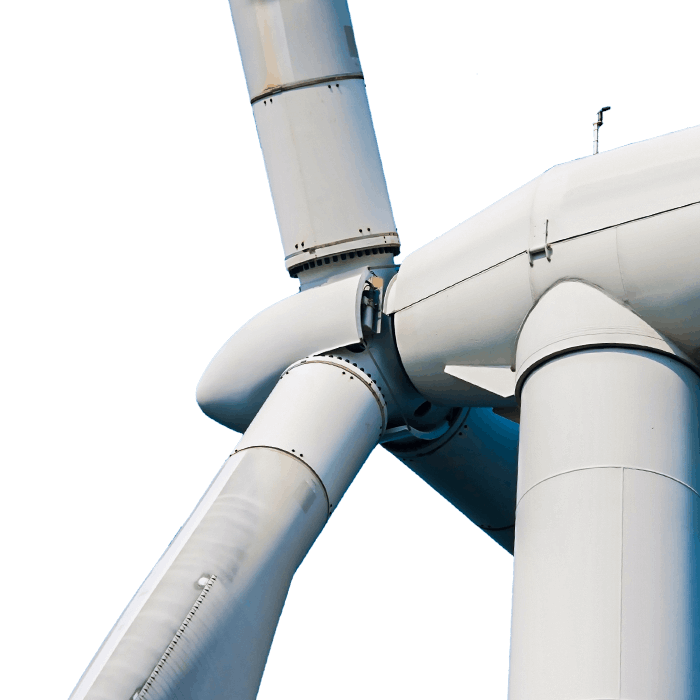

CNC Machining for Wind Energy Components

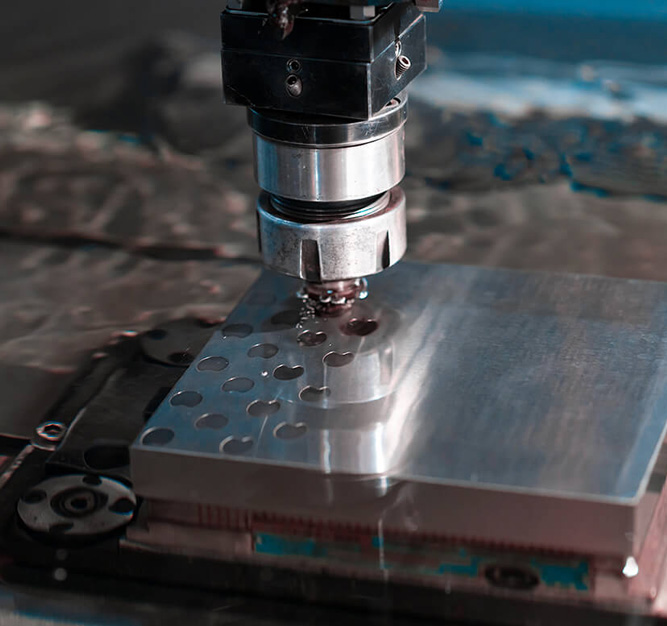

RAM Tool provides precision CNC machining for the wind energy industry, manufacturing critical components for turbines, generators and gear systems. Our machining expertise supports renewable energy manufacturers by producing high-strength, corrosion-resistant parts with reliable performance in demanding environments. From prototype development to full production, RAM Tool’s precision parts power the efficiency and longevity of modern wind systems.

Contact RAM Tool today to discuss CNC machining for the wind energy industry.

Get

Get

The CNC Advantage

The CNC Advantage