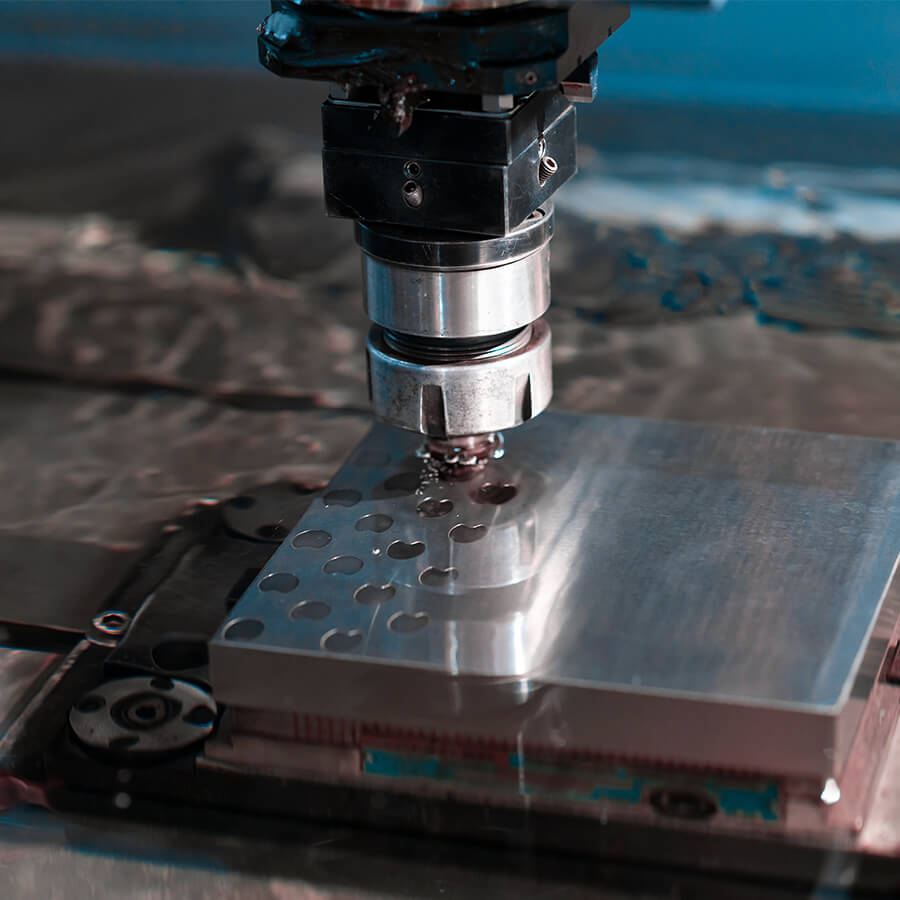

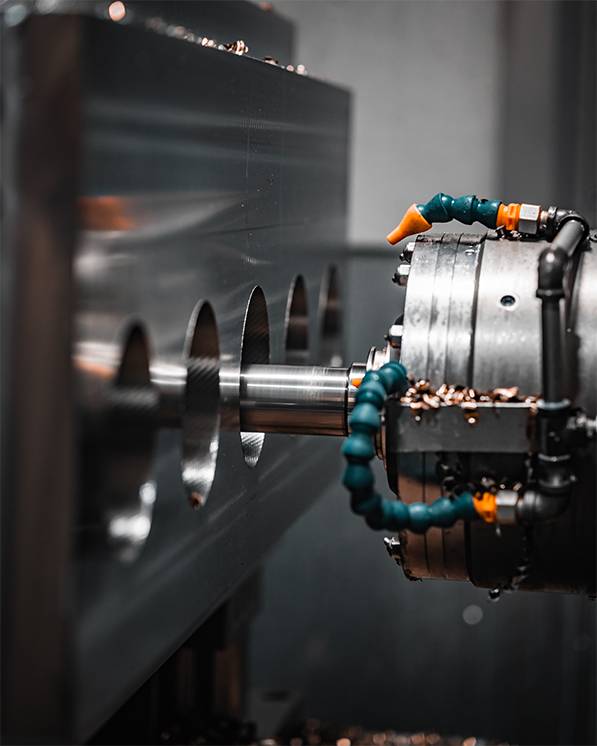

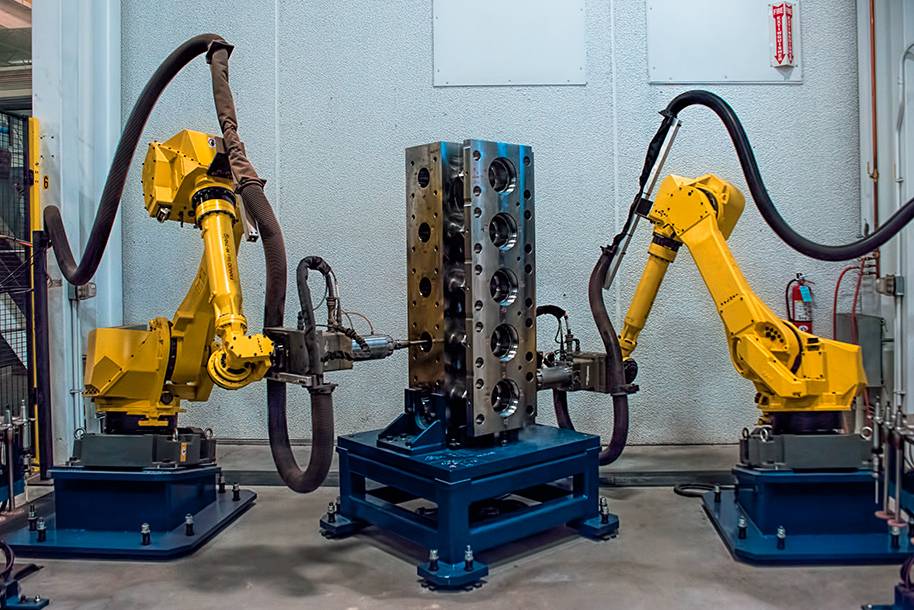

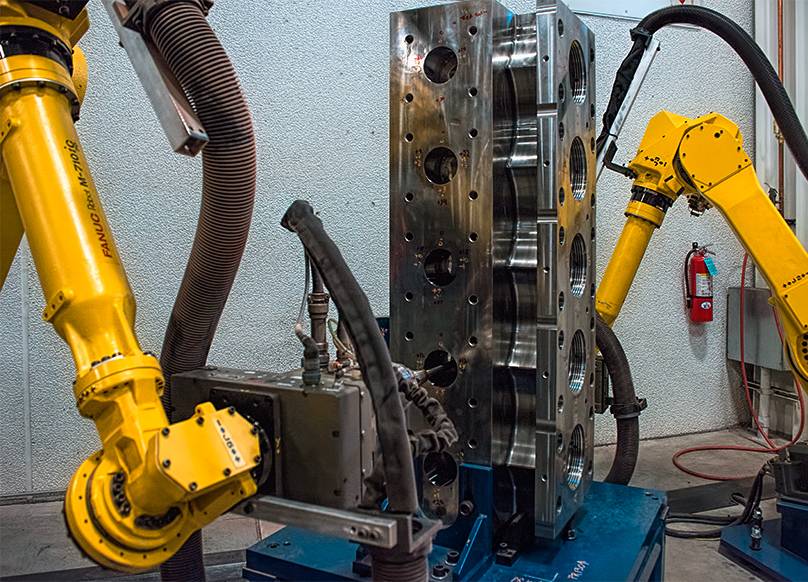

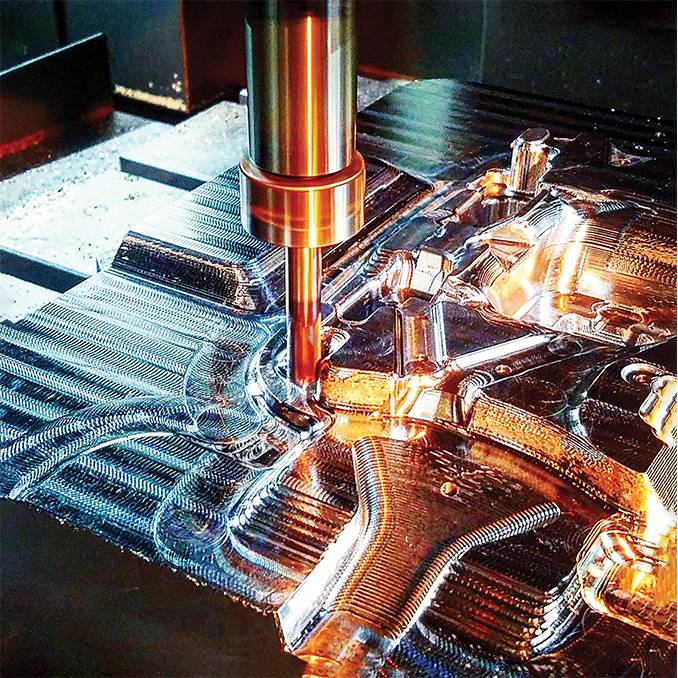

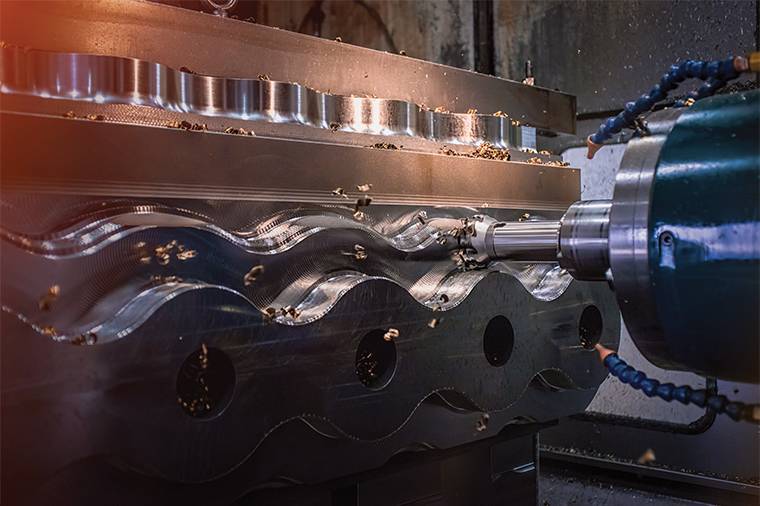

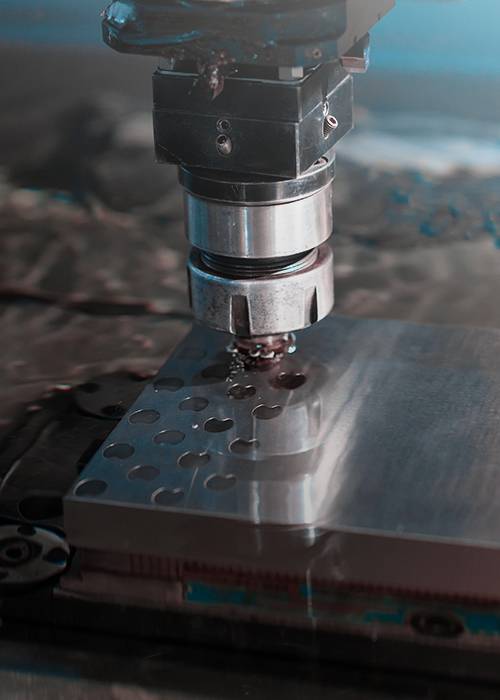

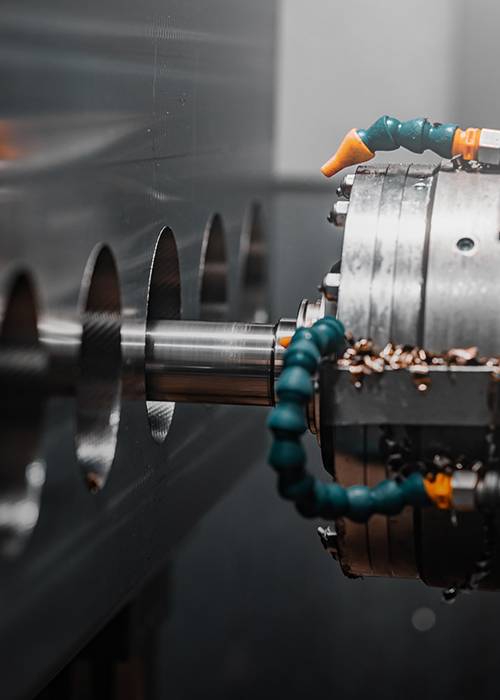

Electrical Discharge Machining Services

RAM Tool offers precision electrical discharge machining services using advanced equipment and skilled operators. Our team brings decades of hands-on experience with EDM machinery like Mitsubishi Wire EDM and sinker systems. Since 2000, our dedicated EDM department has supported complex, high-tolerance projects across industries with precision CNC machining services. We deliver reliable, on-time results through efficient, in-house CNC EDM machining. Contact us today to get started.

Get

Get