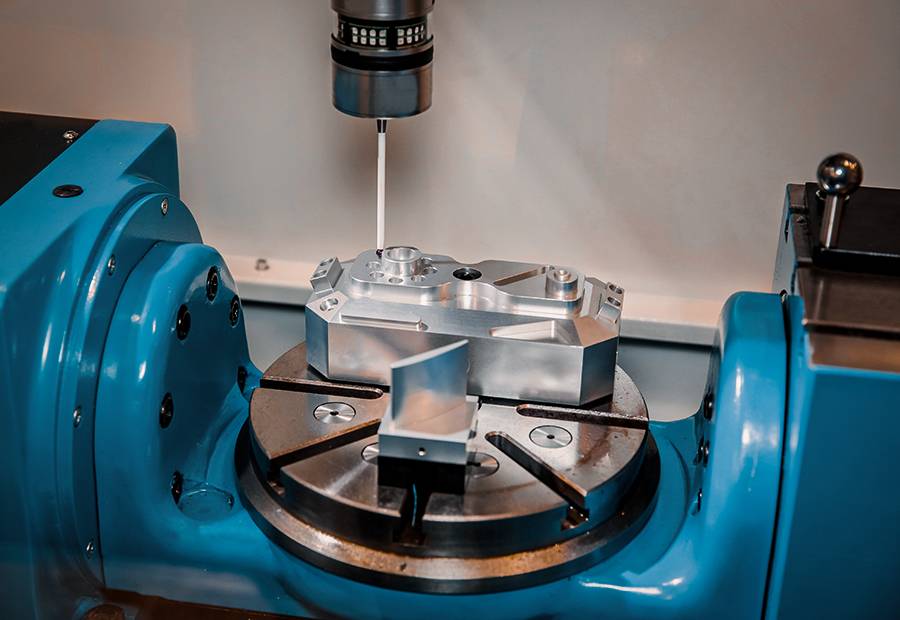

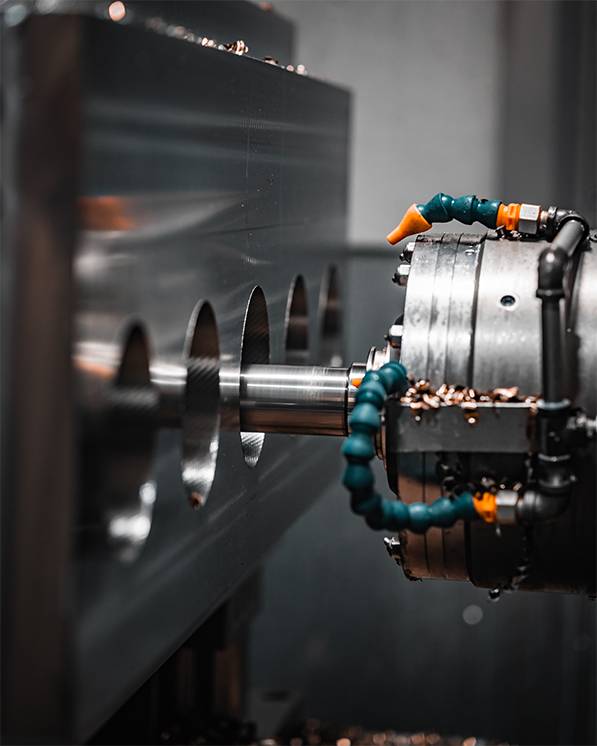

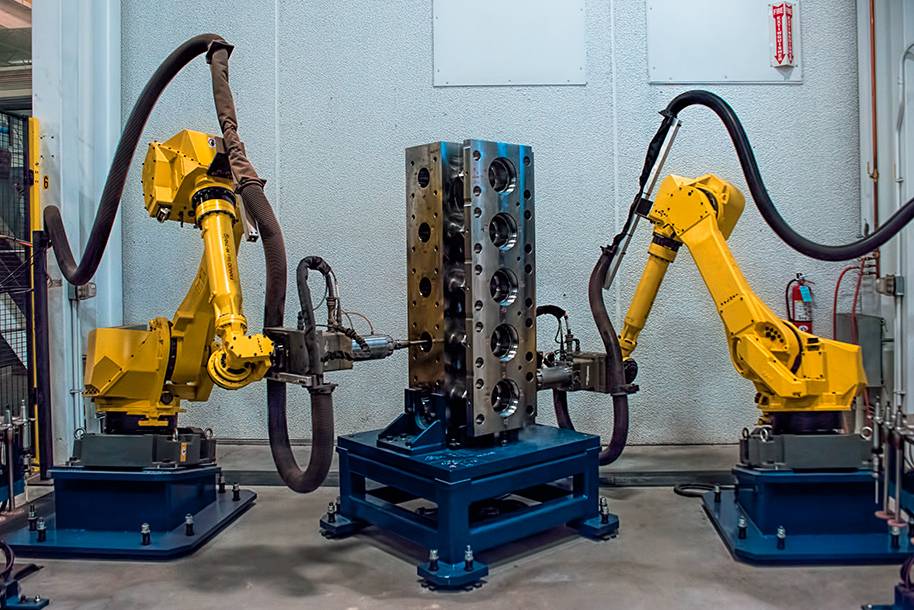

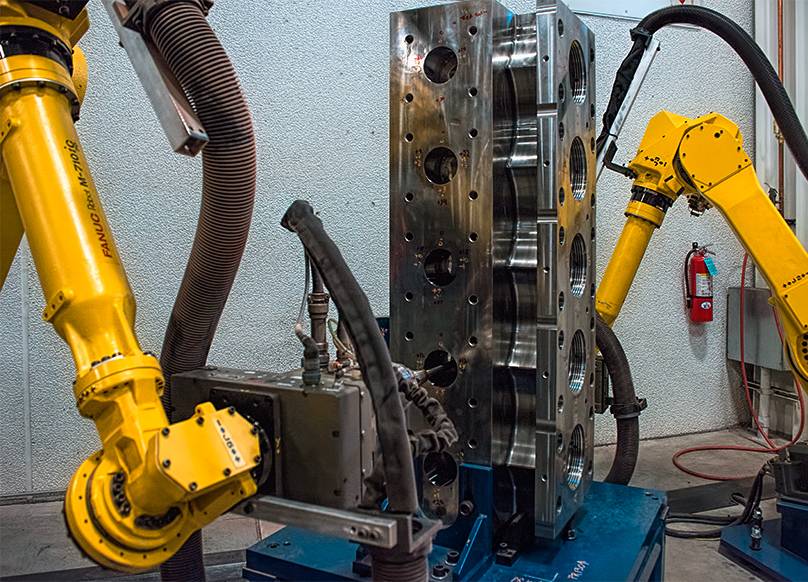

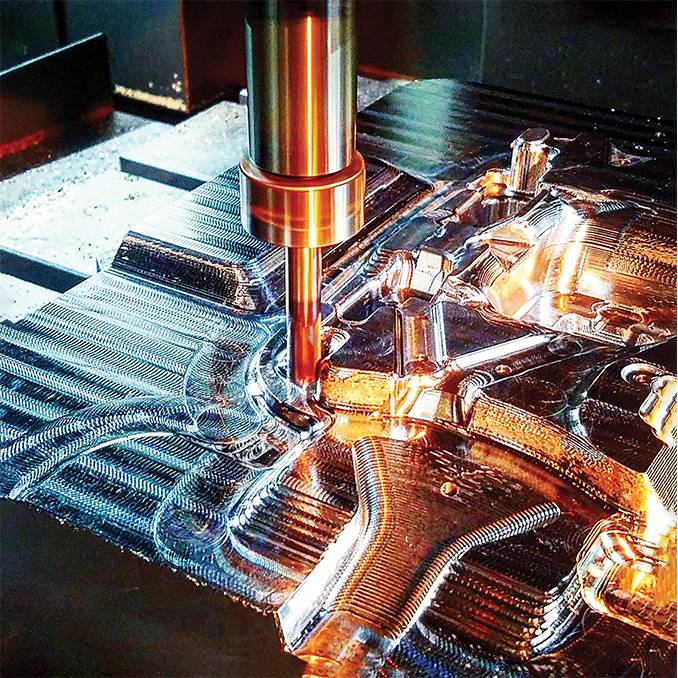

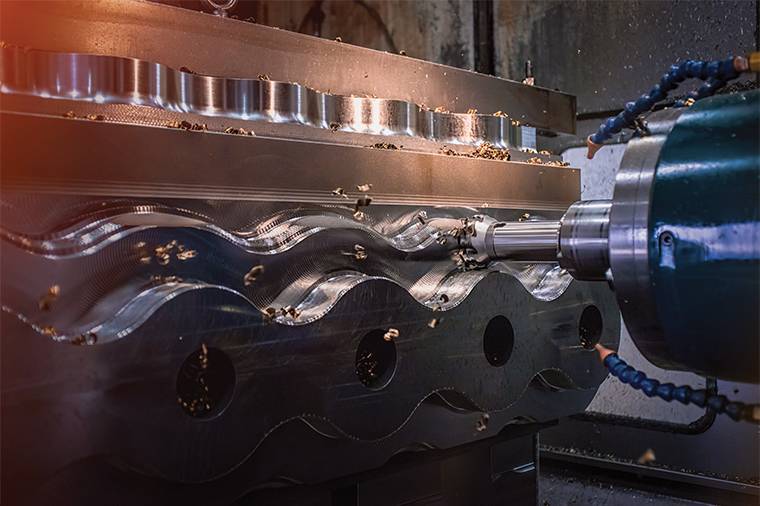

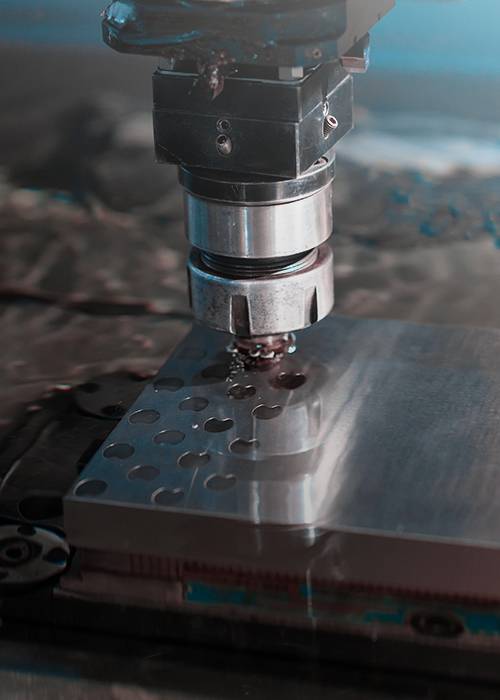

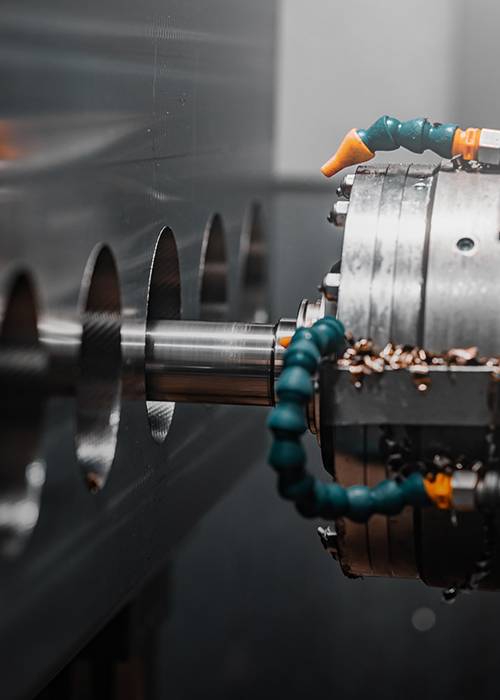

Precision CNC Inspection for Quality Assurance

RAM Tool provides precision CNC inspection services to support reliable part quality for custom and ISO 9001 machining operations. Our in-house CNC inspection department uses advanced technology and proven processes to verify the accuracy and consistency of every part produced by our precision CNC machining services. Contact our team today to get started.

Get

Get