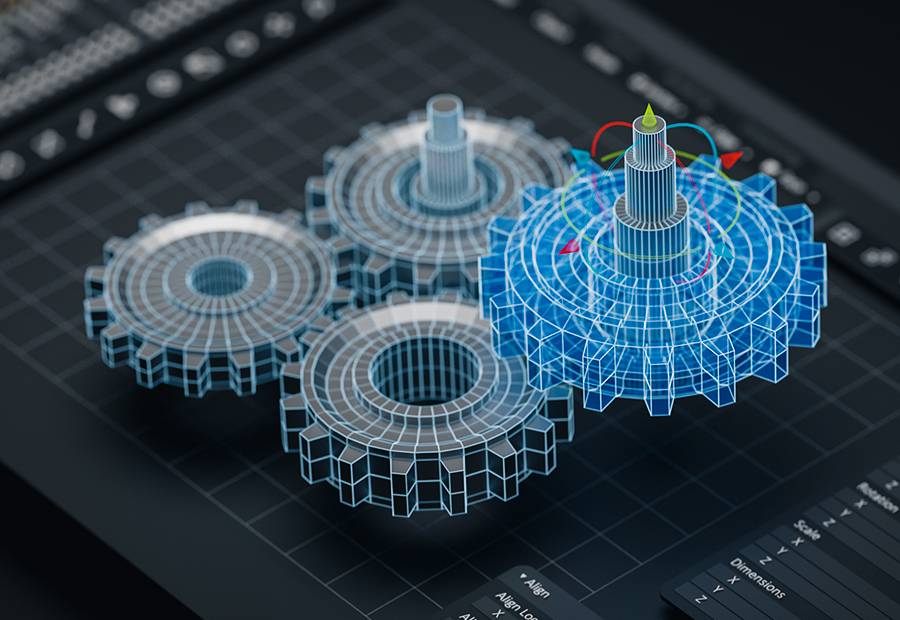

CNC Prototype Tooling Capabilities

RAM Tool is a leading provider of CNC prototype tooling services. Our team of experienced engineers uses advanced computer numerical control technology and software to quickly create prototypes of parts and products with a high degree of accuracy and precision. We bring innovative ideas to life through the prototyping process. Our commitment to quality and customer satisfaction has made us a trusted choice for businesses in need of reliable CNC precision machining capabilities.

Get

Get