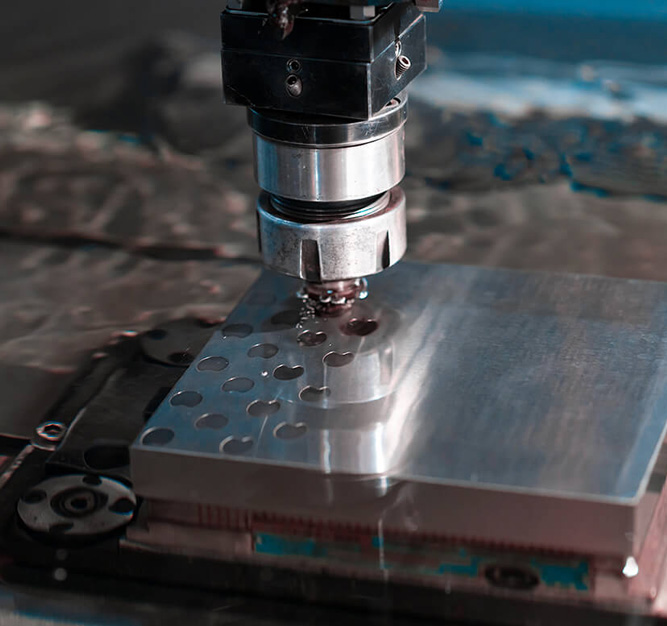

CNC Machining for Oil & Gas Equipment

RAM Tool delivers precision CNC machining for the oil and gas industry, producing high-performance components to support exploration, drilling and refining operations. Our experience with complex parts and demanding materials allows us to deliver consistent quality and long-term reliability for clients across the petroleum sector.

Contact RAM Tool today to learn more about CNC machining for oil and gas applications.

Get

Get

The CNC Advantage

The CNC Advantage