Employment & Career Opportunities at RAM Tool, Inc.

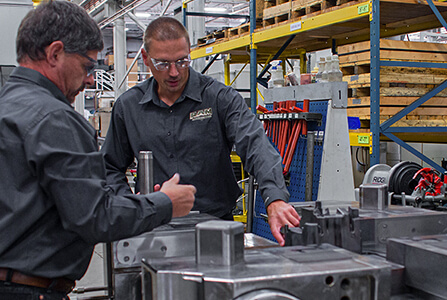

At RAM Tool, we don't just offer jobs—we offer careers that matter. Family-owned, RAM Tool is an industry frontrunner in custom CNC machining and manufacturing building aluminum & zinc die-cast dies. We are currently hiring immediately for several available CNC positions at our 80,000 sq foot facility in Grafton, WI. Browse through our available positions, and find where you can make a mark. Your career at RAM Tool starts here.

**We offer a 2nd shift PREMIUM OF 15% and a sign-on bonus of $1500.**

Get

Get